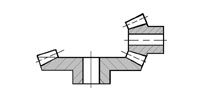

As for all gears, the two conical wheels will only mesh if the modules are equal. As well as that, the conical pitch angles must have a common generator and their projected apexes must meet at a point. These types of gears operate as inseperable pairs. One bevel wheel is designed to work with it's complementary wheel and no other.

A

bevel gear is not compatible with just any old bevel gear

!

Advantages, inconveniences and advise.

- Allows a change of operating angle

- The apex of the projected cones must meet the projected intersection point of the axes (precisely mounted),

- The bushes must be capable of supporting axial forces

- Bevel gears are manufactured in pairs, to work together.

Bevel gear B |

Bevel gear ZB |

| |

Spiral bevel gears

These gears have the double

peculiarity of being beveled and helical at the same time.

Thus they acculmulate the advantages and disadvantages of the two

families.

They are designed for an angle change of 90?where the two axes are concurrent (intersect at a point) and are in the same plane. The assembly must, consequentially, be very precisely done. As for helical gears, the teeth have a helical angle, which must be complementary to that of the other gear of the pair. This helical angle produces a meshing which is silent and very smooth. This method of change in direction allows fast rotational speeds with neither vibration nor noise. These componants must be changed as a pair. It is n possible to change one single wheel.

SMS